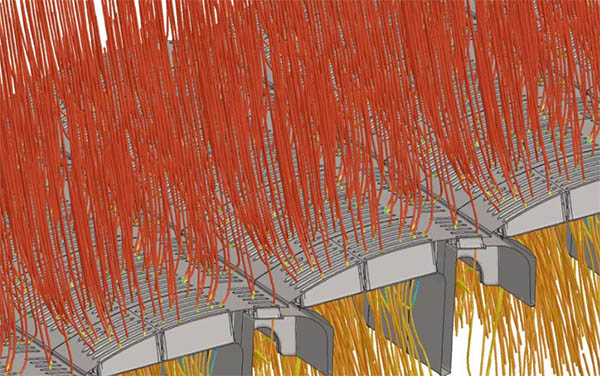

Mus ncig Grates & Saw Grate & hnav phaj ntawm Grate-qhov cub

Raws li Peb tau muab ntau cov ntoo pellet ntau xyoo, peb cov txheej txheem casting thiab cov tshuab ua haujlwm tau ua tiav heev. Nyob rau hauv xyoo tas los, yuav luag tsis muaj cov neeg tsis txaus siab tau txais. Yog tias koj muaj kev thov, thov hu rau peb pab neeg. Peb yuav muab cov kev tshaj lij rau koj ua haujlwm.

Cov khoom siv peb siv rau ntawm cov ntu no feem ntau yog cov hlau tsis kam tiv taus. Kev tiv thaiv tshav kub yog qhov khoom siv nrog lub zog siab thiab ruaj khov siv thaum kub. Nws yog feem ntau siv rau hauv kev lag luam thiab teb xws li metallurgy, kho cua sov, xis mas, fais fab nroj tsuag thiab lwm yam. Raws li cov ntawv thov sib txawv, cov khoom siv no yuav tsum muaj cov tawv zoo, weldability thiab microstructure ruaj khov ntxiv rau qhov kub thiab ua kom muaj zog thiab tiv taus kev kub siab oxidation corrosion.

(1.4848): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Peb tau zoo dua

1. Peb siv plhaub mould precision casting. Cov khoom lag luam tsim los ntawm peb ib txwm muaj cov khoom zoo thiab yuav luag tsis muaj qhov tsis xws casting.

2. Peb tau tsim cov khoom ntim rau cov ntoo pellet tau ntau xyoo. Peb muaj kev nplua nuj ua rau nws.

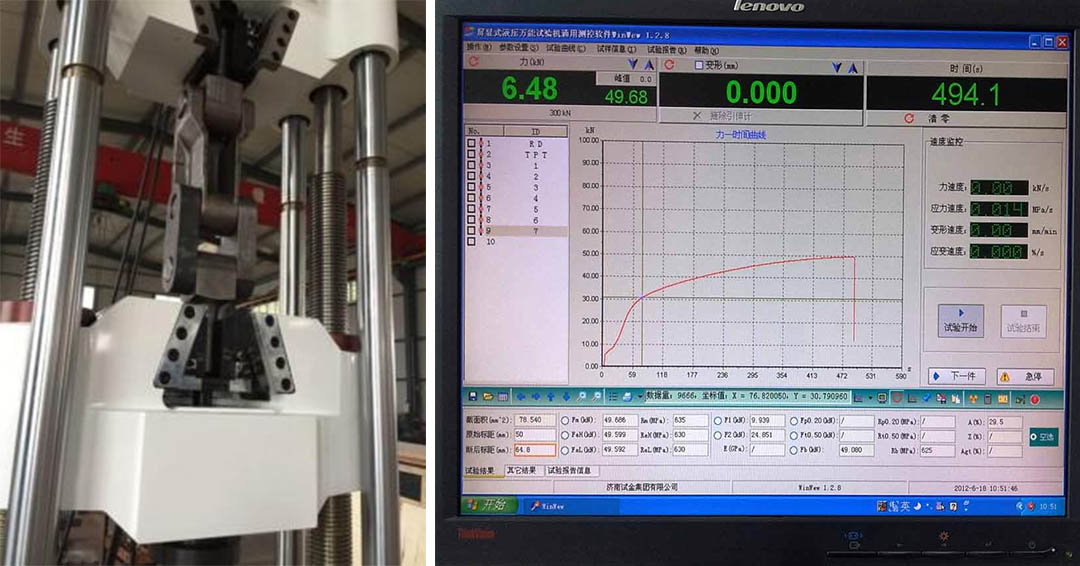

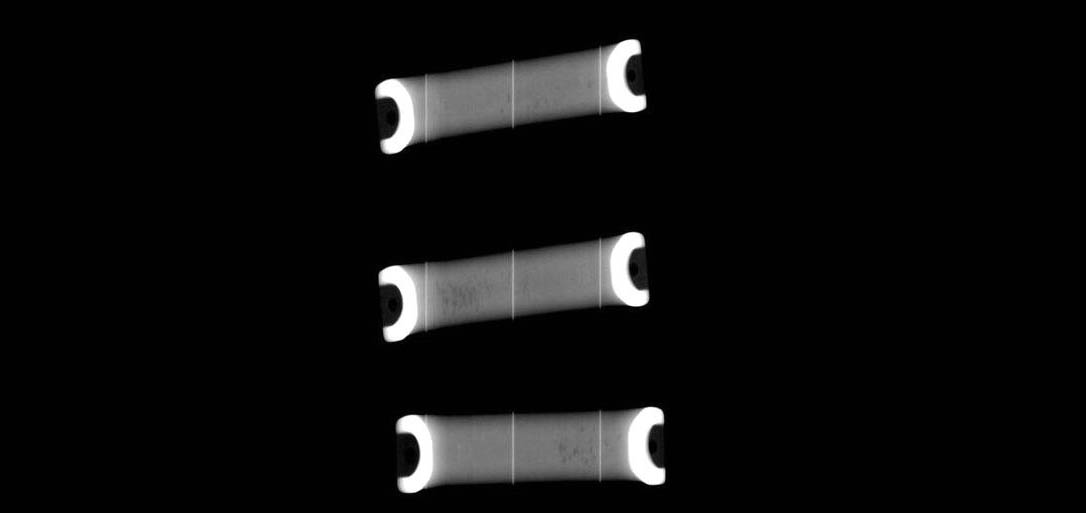

3. Peb tau ua tiav cov khoom kuaj xyuas.

200 tons 'tensile xeem tshuab mus kuaj cov cuab yeej txhua yam ntawm Chain Grate

RT Cov Cuab Yeej Siv los kuaj Sab Sab Ntsuas hauv qhov tsis txaus.

Yog muaj lus nug ntxiv lossis cov lus nug txog kev paub, thov hu rau XTJ Pab Neeg Muab Kev Pab. Peb yuav muab txoj kev daws teeb meem zoo tshaj plaws thiab cov lus hais zoo tshaj plaws raws li koj cov khoom.

Hnav yog thaj teb muaj zog thiab muaj ntau yam hnav.

Hom sib txawv (thiab kev sib xyaw ua ke) ntawm cov hnav ua haujlwm yuav tsum muaj kev sib txawv ntawm cov khoom xaiv thiab qauv tsim.

Kev Siv Abrasive - tshwm sim thaum ib qho chaw uas tawv tawv ntog hla hla lub npoo softer. Feem ntau, txhawm rau kom txo qis hnav koj xav tau cov khoom siv tawv tawv. Cov ntawv thov suav nrog chutes thiab pub kev cia siab uas pom hnav swb.

Erosive Hnav - tshwm sim thaum qhov cuam tshuam cuam tshuam kev hnav ntawm. Raws li zoo li maj mam tshem tawm cov khoom siv los ntawm kev txiav thiab gouging kev ua haujlwm, lub zog tig lub zog ntawm qhov cuam tshuam rau hauv cov khoom tuaj yeem ua rau cov chaw ua haujlwm nyuaj thiab micro tawg uas tuaj yeem ua rau delamination thiab pob zeb. Kev txiav txim siab ntawm cov khoom-tawv zoo li cov khoom siv-hardness zoo li cov qauv tsim cog piv txwv li particle Impingement Angle thiab Velocity yog qhov tseem ceeb los tswj kev hnav tsis zoo. Cov ntawv thov suav nrog pneumatic thiab hydro conveying, grizzlies, ntxaij, thiab cua daj cua dub.

Corrosive Wear -Txoj kev hnav zoo li no yog sib xyaw ua kom xeb & hnav. Cov neeg kho tshuab coj tau nce ntau ntxiv los ntawm cov tshuaj lom neeg cov tshuaj tiv thaiv nruab nrab ntawm cov khoom hnav thiab qhov nruab nrab hauv qhov chaw nruab nrab hauv kev siv, piv txwv li Paddle Mixers hauv Super Phosphate ntau lawm. Cov Khoom Siv Xaiv yog qhov tseem ceeb heev rau kev ua kom zoo rau kev xeb-xaim ntawm cov khoom tivthaiv.

XTJ Kev Tsim Khoom Tshwj Xeeb hauv kev tsim cov coj hlau tsis haum cov khoom lag luam kom tau raws li cov kev nyuaj nyob hauv Chaw Txua Txiag Zeb thiab Cov Hluav Taws Xob.

Peb pab neeg ntawm Metallurgists thiab Cov Kws Tshaj Lij Cav yuav ua haujlwm ze nrog koj kom ntseeg tias peb nkag siab koj cov kev xav tau thiab ua tau raws li koj xav tau ntawm kev sib tw nqi thoob ntiaj teb.

Peb muab ntau yam ntawm cov khoom siv coj los tiv thaiv thiab kev kho cua sov kom muaj peev xwm ua kom tau cov khoom zoo kom ua tau raws li koj cov cai.

Zoo Pob Khoom Ncig Saib Xyuas Lub Zog

Zoo tiav lawm grates

Saw saw kom sib dhos sib dhos