Peb pab neeg ntawm Metallurgists thiab Cov Engineers yuav xyuas kom koj muaj kev ntseeg siab tiav cov khoom xa tawm.

Peb lub chaw soj ntsuam thiab ntsuas cov pa hlau ua Metallographic, Neeg Kho Tshuab, Kev Ntsuas, Kev Ntsuas Tshuaj, thiab lwm yam.

Peb yuav tsim kev tshuaj xyuas thiab kuaj tsoom fwv kom ua tau raws li qhov koj xav tau. Peb Cov Phiaj Xwm Zoo los ntawm ib txwm sim mus rau cov ntawv pov thawj cov ntaub ntawv pov thawj thiab kev ntseeg siab.

Peb muab ib qho suite ntawm Kev Puas Tsuaj thiab Tsis Raug Kev Puas Tsuaj xws li:

1. Co-Ordinate Xab Tshuab CMM

2. Vais Fab-Xias

3. Kev Tshuaj Xyuas Sib Nqus Sib Nqus

4. Tuag Penetrant Soj ntsuam

5. Spectrographic Tshuaj Tshawb xyuas

6. Kev Ntsuas Tensile

7. Peb muaj 7. Kev Ntsuas Pom

8. 8. Khoov Kev Kuaj

9. 9. Txoj Kev Kuaj Lub Neej

10. Metallography

Tshuaj lom neeg muaj pes tsawg leeg tsom xam

Tom qab cov ntaub ntawv raw yog melted rau hauv molten hlau. Peb siv lub tshuab ntsuas hluav taws xob los kuaj cov khoom ntawm molten steel ua ntej casting kom paub tseeb tias cov khoom muaj cov qib steel muaj qhov tseeb.

Kev Ntsuas Qhov Loj

Kev ntsuas qhov ntev yog ua raws li cov duab kos los ntsuas seb qhov casting qhov ntev yog nyob rau hauv qhov ua siab ntev, yog li kom paub qhov yuam kev ntawm cov duab thiab qhov ntev. Tsis tas li ntawd, qhov tseeb ntawm machining datum txoj hauj lwm, kev faib tawm ntawm cov khoom noj tau txais nyiaj thiab phab ntsa tuab sib txawv yuav tsum ua tib zoo kuaj.

Tshuaj Xyuas Particle Sib Nqus (MPI)

MPI yog cov kev sim ua rau tsis muaj kev puas tsuaj (NDT) cov txheej txheem txhawm rau txhawm rau kuaj cov nplaim thiab cov dej hauv av tsis muaj dab tsi hauv cov khoom siv hlau xws li hlau, npib tsib xee, cobalt, thiab qee yam nws alloys. Cov txheej txheem muab tso rau qhov chaw ua haujlwm sib nqus rau hauv feem. Cov thooj tuaj yeem raug tsim los ntawm kev qhia tawm ncaj qha lossis tsis ncaj qha. Kev nqus ncaj qha tshwm sim thaum lub tshuab hluav taws xob dhau los ntawm qhov khoom ntsuas thiab qhov chaw sib nqus tau tsim nyob rau hauv cov khoom siv. Indirect magnetization tshwm sim thaum tsis muaj hluav taws xob hluav taws xob dhau los ntawm qhov khoom ntsuas, tab sis ib qho chaw sib nqus tau thov los ntawm qhov chaw sab nraud. Cov kab sib nqus ntawm lub zog sib luag yog txiav mus rau qhov kev taw qhia ntawm lub tshuab hluav taws xob, uas tej zaum yuav hloov mus rau qhov hloov tam sim no (AC) lossis qee hom kev siv hluav taws xob tam sim no (DC) (kho qhov hluav taws xob AC).

Kev Tshuaj Ntsuam Ultrasonic (UT)

UT yog tsev neeg tsis muaj kev sib tw kev xeem zoo raws li kev tshaj tawm ntawm ultrasonic vuag hauv cov khoom lossis cov khoom ntsuas. Hauv kev siv UT, feem ntau luv luv ultrasonic mem tes-vuag nrog qhov chaw nruab nrab ntawm 0.1-15 MHz, thiab qee zaus txog 50 MHz, raug xa mus rau hauv cov khoom siv los nrhiav cov kev ua tsis tau sab hauv lossis cov khoom siv ntawm cov khoom. Ib qhov piv txwv dav dav yog ultrasonic ntsuas kev ntsuas, uas ntsuas cov tuab ntawm qhov khoom ntsuas, piv txwv, txhawm rau soj ntsuam cov yeeb nkab xeb.

Txoj Kev Kuaj Mob

Kev tawv yog qhov muaj peev xwm ntawm cov khoom siv los tiv lub siab ntawm cov khoom nyuab rau hauv lawv cov chaw. Raws li cov xeem sib txawv thiab ntau yam ntawm cov khoom siv tau yooj yim, cov chaw ua haujlwm hardness tau muab faib ua Brinell hardness, Vickers hardness, Rockwell hardness, micro Vickers hardness, thiab lwm yam sib txawv muaj cov qauv sib txawv, uas tsim nyog rau cov khoom sib txawv lossis qee zaus nrog tus yam ntxwv sib txawv.

Kev Ntsuas Hluav Taws Xob (RT)

(RT lossis X-ray lossis Gamma ray) yog ib qho kev sim uas tsis muaj kev puas tsuaj (NDT) txoj kev ntsuas uas kuaj cov ntim ntau npaum li cas. Cov duab xoo hluav taws xob (Xoo hluav taws xob) siv duab xoo hluav taws xob thiab gamma-rays los tsim duab hluav taws xob ntawm lub cev ntaj ntsug, qhia txog txhua yam kev hloov pauv ntawm tuab, qhov tsis xws luag (sab hauv thiab sab nraud), thiab cov ntsiab lus sib dhos kom ntseeg tau tias zoo tshaj plaws hauv koj txoj haujlwm.

Cuab Yeej Cuab Yeej Cuab Yeej Cuab Tam

Peb lub tuam txhab tau nruab nrog 200 tons thiab 10 tons lub tshuab tensile. Nws tuaj yeem siv los sim cov cuab yeej lub zog ntawm qee yam khoom tshwj xeeb.

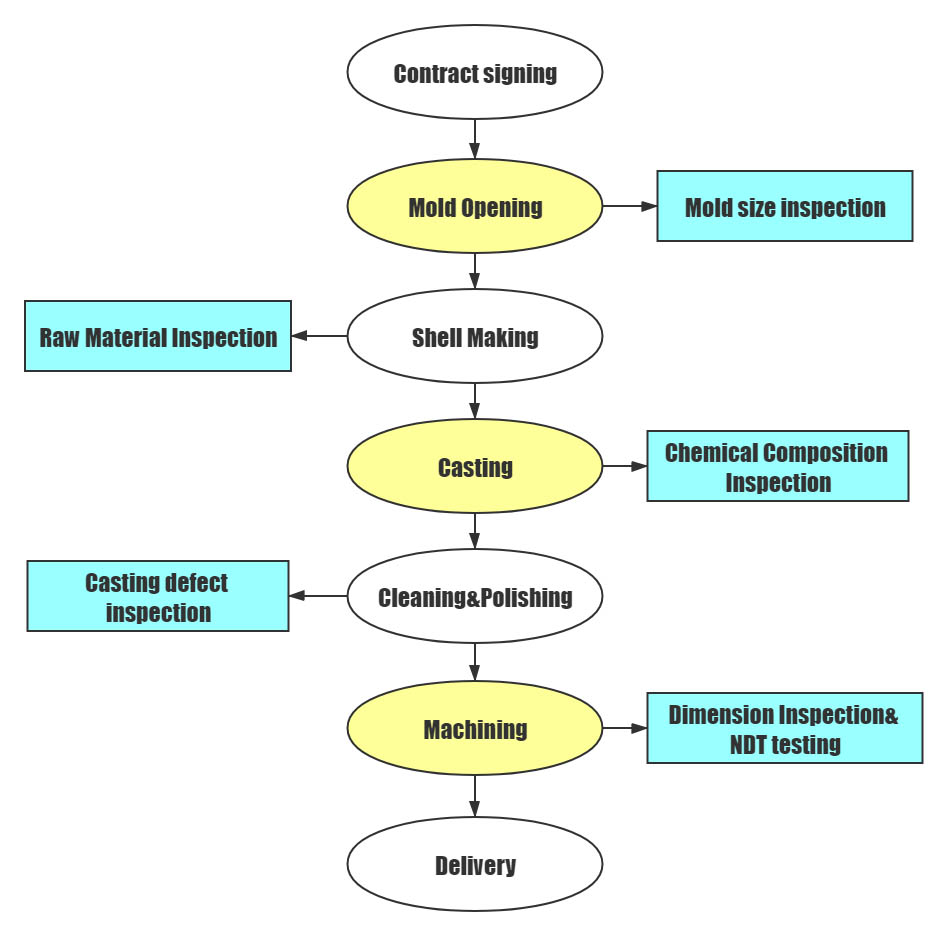

Soj Ntsuam Flow Daim Ntawv

Ua tau zoo, xoom tsis tiav yog lub hom phiaj peb ib txwm ua raws. Kev pom zoo ntawm cov neeg siv khoom yog qhov kev tsav tsheb rau peb kev nruam ntej. Tom qab ntsib ntau dua kaum xyoo ntawm kev ua lag luam thoob ntiaj teb, peb tau ua qhov kev txhim kho tseem ceeb ntawm txoj kev tswj kom zoo. Xyoo tsis ntev los no, peb tau nce ntau ntawm cov khoom siv tshaj kev ntsuas siab xws li 200/10 Tensile test tshuab, cov cuab yeej kuaj ultrasonic, Cov khoom siv sib nqus cov hlau nplaum, cov khoom xoo hluav taws xob tshawb nrhiav, cov khoom siv tshuaj lom neeg ob lub tshuab tshuaj xyuas, Rockwell hardness tester thiab lwm yam. Cov.