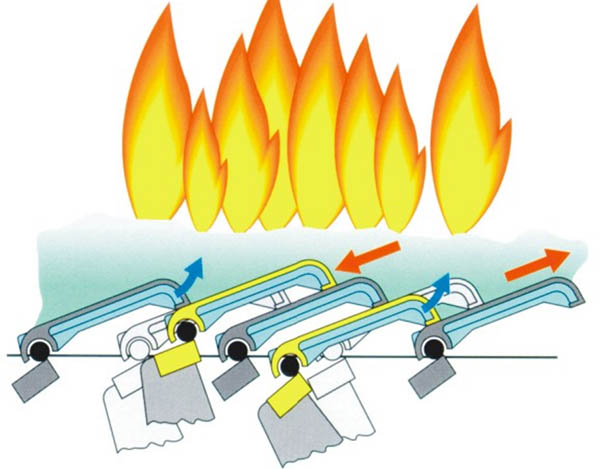

Cam khwb cia steel grate tuav, hnav qhov chaw ntawm cov khib nyiab rau lub zog cua sov

1. Txheej txheem casting: Plhaub pwm precision casting

2. Qib steel: GX130CrSi29 (1.4777) (Kuj tuaj yeem ua raws li koj qhov yuav tsum tau ua)

3. Cov Viv Ncaus Cov Khoom Siv Tau Zoo: DIN EN ISO 8062-3 qib DCTG8

4. Geometrical Tolerance ntawm cam khwb cia: DIN EN ISO 8062 - qib GCTG 5

5. Daim Ntawv Thov: Nkim mus rau cov nroj tsuag ua kom lub zog.

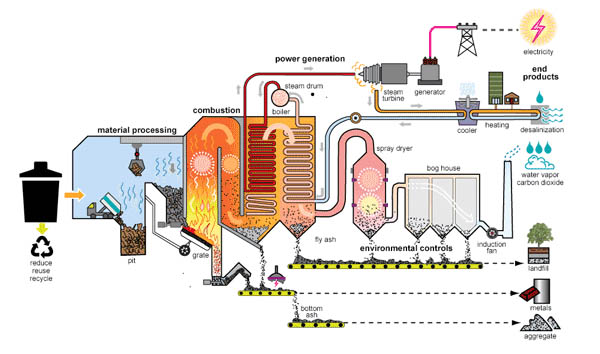

Kev khib nyiab yog tam sim no teeb meem thoob ntiaj teb. Cov khib nyiab rau lub zog yog qhov kev kho mob tam sim no tsim nyog tshaj plaws. Nyob rau hauv xyoo tas los, ntau lub tebchaws uas muaj zog kev lag luam zoo tau pib them sai sai txog qhov no. Nyiaj ntau tau nqis peev rau kev tsim kho cov ntoo txauv hluav taws xob tsis muaj zog. Qhov no tsis tsuas yog coj kev txhim kho zoo rau peb ib puag ncig. Tib lub sijhawm, nws tau coj peb cov txiaj ntsig nyiaj txiag zoo.

Raws li pom hauv daim duab, cov nyom yos ua si lub luag haujlwm tseem ceeb hauv kev rhuav tshem cov khoom pov tseg. Nyob rau hauv qhov kub thiab qhov chaw tsis tshua muaj kev kub ntxhov, Lub txiaj ntsig zoo yuav ua rau muaj kev cuam tshuam zoo ntawm cov khib nyiab pov tseg, thiab nws lub neej muab kev pab luv heev. Koj yuav tsum tau hloov nws ntau zaus.

Txawm li cas los xij, nrog dhau 10 xyoo casting kev, peb tuaj yeem daws cov teeb meem rau koj.

Hlau Qeb peb feem ntau siv. (Nws kuj tseem tuaj yeem ua qhov koj xav tau.)

Tshuaj lom neeg muaj pes tsawg leeg% cov hlau GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechanical zog (ASTM A297 Qib HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Elongation: hauv 2 hauv: Min 10% | |

| Hardness: Min 200 BHN (3 chaw ntawm speciment) " | |

| Microstructure / Metallography | Feem ntau cov Austenitic qauv uas muaj cov carbides dispersed |

| SoundnessTest / Xoo hluav taws xob lossis UT | RT rau ASTM E446 Qib II |

| UT rau ASTM A609 Qib II | |

| NDT / LPI lossis MPI | MPI raws li ASTM E709 / E125 QIB II |

| LPI as per ASTM E165 Qib II " | |

| Kev Soj Ntsuam Thaum Kawg | ASTM A802 Qib II |

| Pob | Rooj plaub hlau lossis ntoo rooj plaub. |

Peb Lub Lag Luam Tseem Ceeb

OEMs thiab engineering tuam txhab

Nkim mus rau cov nroj tsuag zog

Cov tuam txhab ua haujlwm

Chav nyob biomass

Kev tsim hluav taws xob-thee zog

Cov tuam txhab pabcuam rau kev saib xyuas kev ua haujlwm

Txawv sib txawv ntawm OEM grate tuav

Zoo tiav lawm grate tuav

Tus Txheej Txheem Loj Thiab nruj Tswjhwm Zoo Yog Vim li cas koj yuav xaiv peb

Yog muaj lus nug ntxiv lossis cov lus nug txog kev paub, thov hu rau XTJ Pab Neeg Muab Kev Pab. Peb yuav muab txoj kev daws teeb meem zoo tshaj plaws thiab cov lus hais zoo tshaj plaws raws li koj cov khoom.