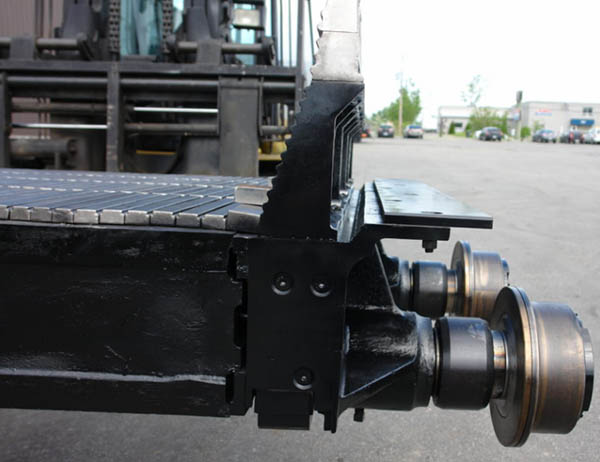

Grate bar thiab Sab phab ntsa, Hnav Sab ntawm pallet tsheb thiab sinter / pellet tsheb

1. Txheej txheem casting: Plhaub pwm precision casting

2. Qib steel: 1.4777 1.4823 1.4837 1.4848

3. Cov Viv Ncaus Cov Khoom Siv Tau Zoo: DIN EN ISO 8062-3 qib DCTG8

4. Geometrical Tolerance ntawm cam khwb cia: DIN EN ISO 8062 - qib GCTG 5

5. Daim Ntawv Thov: Hnav Qhov ntawm cov pallet tsheb thiab sinter tsheb.

Peb yog tus muab khoom lag luam rau pallet tsheb thiab sinter tsheb tuam ntxhab thiab cov cav hlau loj. Nrog ntau tshaj 10 xyoo 'kev paub dhau los, cov khoom tiv thaiv uas tsim los ntawm peb ib txwm muaj cov cuab yeej zoo txhua yam thiab zoo nrum nto. Lub tshuab thev naus laus tau tswj tau zoo ntawm peb cov nqi tsim khoom, kom koj tuaj yeem xaj cov khoom tsim qis los ntawm peb. Xyoo tsis ntev los no, qhov nce ntawm qhov peev xwm ntau lawm tau lav koj lub hnub xa khoom.

Hlau Qeb peb feem ntau siv. Nws kuj tuaj yeem ua tau raws li koj qhov yuav tsum tau ua.

Tshuaj lom neeg muaj pes tsawg leeg% cov hlau GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Tshuaj lom neeg muaj pes tsawg leeg% hlau GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

N |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechanical zog (ASTM A297 Qib HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Elongation: hauv 2 hauv: Min 10% | |

| Hardness: Min 200 BHN (3 chaw ntawm speciment) " | |

| Microstructure / Metallography | Feem ntau cov Austenitic qauv uas muaj cov carbides dispersed |

| SoundnessTest / Xoo hluav taws xob lossis UT | RT rau ASTM E446 Qib II |

| UT rau ASTM A609 Qib II | |

| NDT / LPI lossis MPI | MPI raws li ASTM E709 / E125 QIB II |

| LPI as per ASTM E165 Qib II " | |

| Kev Soj Ntsuam Thaum Kawg | ASTM A802 Qib II |

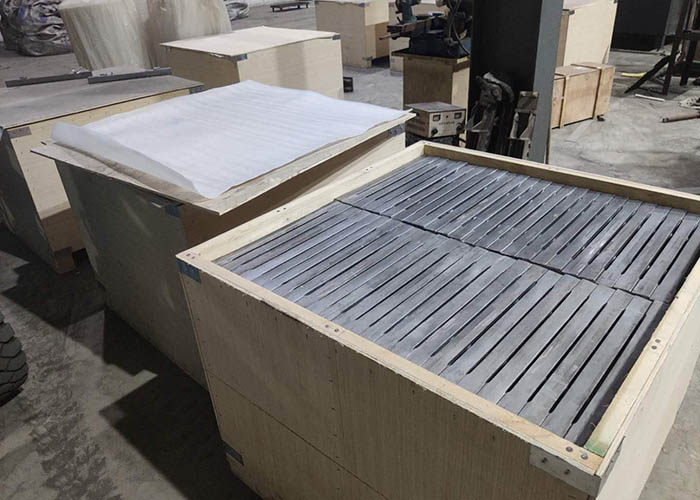

| Pob | Rooj plaub hlau lossis ntoo rooj plaub. |

Hauv kev lag luam muaj kev sib tw tam sim no, tswj kom zoo thaum txo cov nqi tuaj yeem yog qhov nyuaj rau txhua lub lag luam.

Tab sis koom tes nrog xtj, koj tsis tas yuav xav txog nws. Peb yog lub hoobkas tshaj lij, xa khoom tom qab ntau lawm. Thiab muaj cov kws tshaj lij cov neeg ua haujlwm thiab pab pawg tom qab muag kom muab kev pabcuam rau koj. Txoj kev no, koj tuaj yeem tau txais kev pabcuam zoo tshaj plaws thaum txo tus nqi.

Yog muaj lus nug ntxiv lossis cov lus nug txog kev paub, thov hu rau XTJ Pab Neeg Muab Kev Pab. Peb yuav muab txoj kev daws teeb meem zoo tshaj plaws thiab cov lus hais zoo tshaj plaws raws li koj cov khoom.